As one of the top LED panel lighting manufacturers and suppliers, we must very familiar with its raw materials and have rich production experience to manufacturing high quality LED panel lights. Let our 10 years of production experience to tell you what materials are the LED panel lights made of.

1. Diffuser for LED Ceiling Panel Light

The LED diffusion plate has the characteristics of high diffusivity and high light transmittance. It can effectively converts the point light source into a soft and uniform surface light source. It is widely used in LED panel lights.

The diffusion plate includes the following categories according to material:

PMMA diffusion plate: using polymethyl methacrylate as the substrate

PS diffuser: using polystyrene as the base material

PC diffuser: polycarbonate

PP diffuser: polypropylene

Different materials of the diffusers have quite different diffusivity and light transmittance.

PMMA light transmittance is about 92%. PC light transmittance is about 88%. PS light transmittance is about 80%. Although PMMA has high light transmittance, it has poor anti-aging ability; PC has strong anti-aging ability, moderate light transmittance, but high price; PS is cheap, but poor light transmittance. LED panel lights manufacturers and suppliers will use PC or PS for diffuser. if you get a cheap LED panel light price list from your LED panel lights suppliers, it may be use PS diffuser.

One side of the diffusion plate is smooth, which helps to improve the light transmittance; the other side of the diffusion plate is matte, which can effectively increase the astigmatism effect and reduce the glare value.

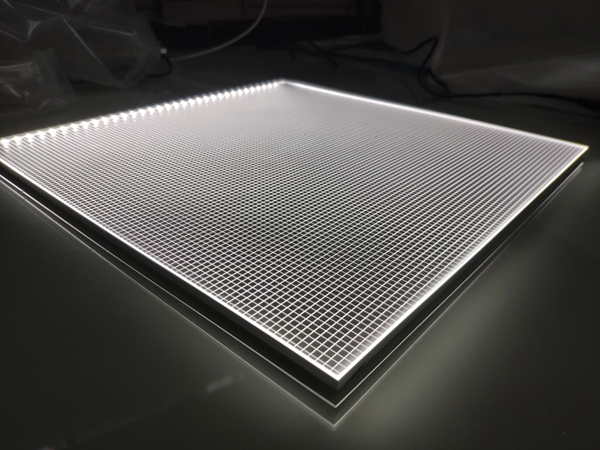

2. Light Guide Plate for LED Ceiling Panel Light

The main function of the LED Light Guide Plate has two points:

The luminous flux of the LED point light source is evenly distributed on the entire plane.

Through the reflection of the light guide plate, the luminous flux can be effectively used and the distribution of light can be controlled. It is an important step in the quality control of LED flat panel light.

There are two types of Light Guide Plate materials

PMMA Light Guide Plate: consist of polymethyl methacrylate

PS Light Guide Plate: consist of polystyrene

The material of the light guide plate is different and the light guide rate is also different. The price of PMMA is high and its weather resistance is good. Its light guide rate is about 92%.

The price of PS Light Guide Plate is low. Its weather resistance is poor and the light guide rate is about 88%. In order to meet the needs of the market, the thickness of the light guide plate has 2T (2mm) and 3T (3mm) options. The thicker the Light Guide Plate, the better the light guide effect.

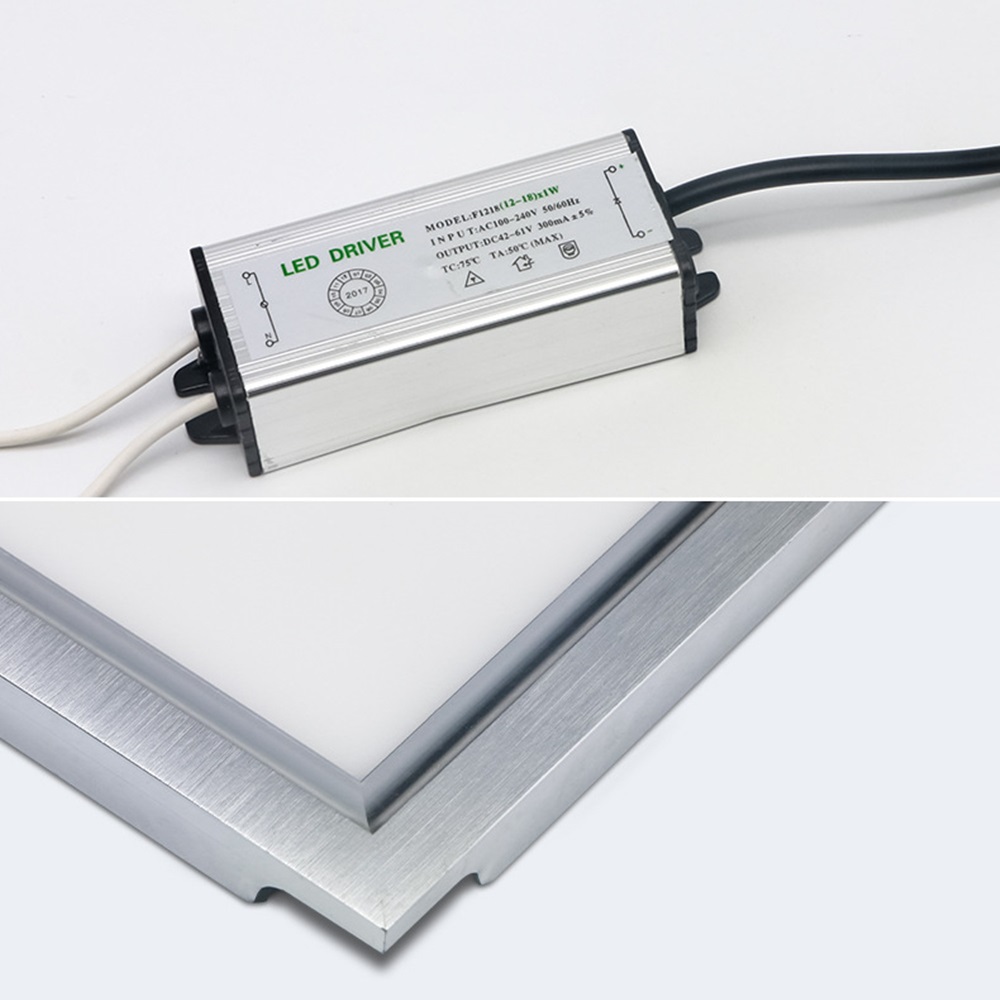

3. LED Driver for LED Ceiling Panel Light

There are two types of external LED drivers for ceiling light panels.

1. Constant current driver. This kind of LED driver has high efficiency. Its PF value is as high as 0.95 and the price is competitive. LED panel lights manufacturers and suppliers usually use such power supply.

2. Constant voltage constant current driver is stable. But the efficiency is low and the price is high. The PF value is around 0.5. Unless the customer ask for it, otherwise no LED panel light manufacturer and supplier will use it.

4. LED Chip for LED Panel Light

Years ago, LED panel lighting manufacturers and suppliers used SMD3014, SMD3528, SMD5630 and SMD5730. Now, for the most competitive price, all LED panel lighting manufacturers and suppliers use SMD4014 or SMD2835. SMD4014 is used with 2T (2mm) light guide plate; SMD2835 is used with 3T (3mm) light guide plate.

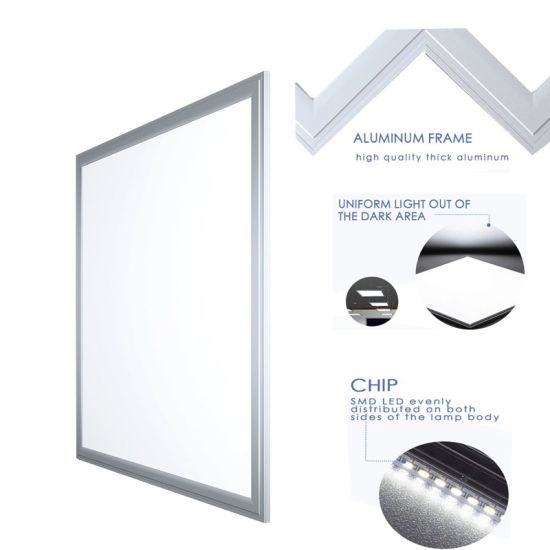

5. Aluminum Frame for LED Flat Panel

The aluminum frame is the main channel for heat dissipation of LED chips. The materials of LED round panel lights, LED square panel lights and LED surface panel lights are die-cast aluminum; 2×2 LED flat panel, 2×4 LED flat panel, etc. are 6063 aluminum.

No matter what material is used as the heat dissipation channel, we should ensure that the temperature of the LED chips should not exceed the value it can withstand. The junction temperature of the LED chips is 120℃, and exceeding this temperature will burn the LED chips.

So the LED panel lights manufacturers should control the appropriate power corresponds to the aluminum frame size.

6. Reflective paper for LED Panel Light

The role of reflective paper is to reflect the residual light on the back of the light guide plate to improve the LED flat panel light light efficiency. Generally the material is PET.

7. Backplane for the LED Flat Panel

The function of the backplane is to seal the LED flat panel light. The material is generally aluminum or iron. It also helps the LED chips to dissipate heat.